PENETRANT TESTING & INSPECTION SERVICES

Penetrant testing, also known as dye penetrant inspection, is a non-destructive testing method used to detect surface-breaking defects in materials such as metals, plastics, ceramics, and composites. It is commonly used in industries such as structural, power generation, nuclear, aerospace, automotive, and manufacturing.

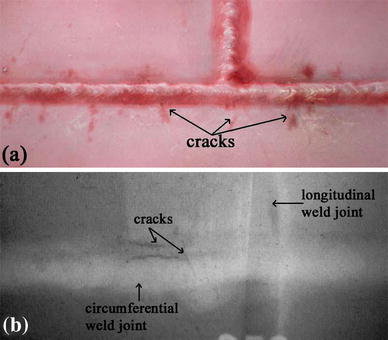

The process involves applying a liquid penetrant, usually a brightly colored dye, to the surface of the material being tested. After a period of time, the excess penetrant is removed, and a developer is applied. The developer draws the penetrant out of any surface-breaking defects, creating a visible indication of the flaw.

Penetrant testing can detect defects such as cracks, porosity, laps, and seams. It is a relatively simple and inexpensive testing method that can be used on a wide variety of materials and surface geometries. However, it is limited to detecting only surface-breaking defects and cannot detect defects that are hidden beneath the surface.

Penetrant testing is typically performed in accordance with industry standards such as ASTM E1417 or ASME BPVC Section V. It is often used in conjunction with other non-destructive testing methods such as magnetic particle testing and ultrasonic testing to provide a more complete evaluation of a material's condition.

Xenogenesis uses penetrant testing on many different metals, alloys and components.

COMMON TEST STANDARDS AND CODES

We offer penetrant testing compliant with many different industry standards and codes to include:

| Testing Standard | Testing Codes |

| API – American Petroleum Institute | 1104 (Welding of Pipelines and Related Facilities) |

| ASME – American Society of Mechanical Engineers | BPVC Section V, Section IX, B31.1, B31.3 |

| ASTM – American Society for Testing and Materials | E1219, E1220, E1417 |

| AWS – American Welding Society | D1.1, D1.2, D1.3, D1.4, D1.5, D1.6 |

| AWWA – American Water Works Association | AWWA C200 |

| Client Specific | Test Services |