POSITIVE MATERIAL IDENTIFICATION SERVICES

Positive Material Identification (PMI) is a non-destructive testing (NDT) method used to verify the chemical composition of a metal or alloy. PMI is often used in industries where the accurate identification of materials is critical, such as aerospace, oil and gas, nuclear, and power generation.

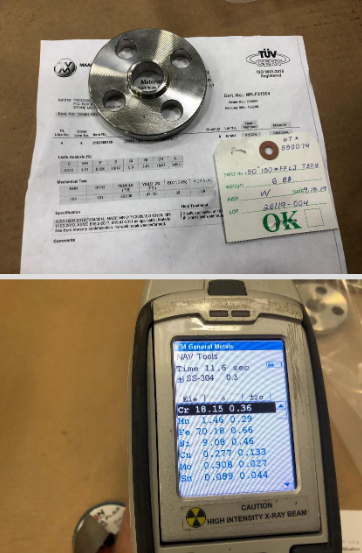

PMI is typically performed using handheld devices, such as X-ray fluorescence (XRF) analyzers or optical emission spectrometers (OES), which use various methods to detect and analyze the elemental composition of the material. The device is placed on the surface of the material, and a small amount of the material is vaporized or excited with a beam of radiation. The resulting emissions are then analyzed to determine the composition of the material.

PMI is important to ensure that the correct material is used in a specific application, and to prevent material mix-ups or substitutions that can lead to costly failures. PMI is also used to verify the integrity of welds and other critical components, as well as to identify and quantify corrosion and other forms of material degradation.