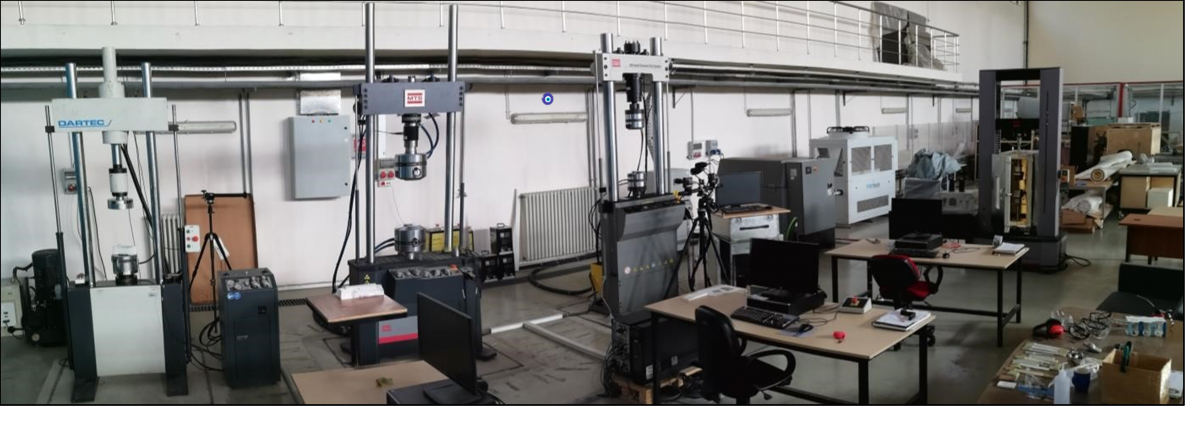

MECHANICAL LABORATORY TESTING SERVICES

Mechanical testing refers to the process of testing the mechanical properties of materials, components, or systems. The objective of mechanical testing is to determine the behavior of a material under different loading conditions such as tension, compression, bending, and torsion. The results of mechanical testing are used to determine the strength, ductility, toughness, and other mechanical properties of the material.

Mechanical testing can be performed using a wide range of testing machines and equipment, depending on the type of material being tested and the specific properties being evaluated. Examples of mechanical testing techniques include tensile testing, compression testing, shear testing, bending testing, torsion testing, and fatigue testing.

Mechanical testing is widely used in engineering, manufacturing, and materials science, as it provides valuable information about the properties of materials that are critical to the design and development of products, structures, and systems.

- Bend Testing – Pipe and Tube

- Bend Testing – Plate, Sheet & Bar

- Machining Services

- Custom Fixtures and Testing

- Load Testing

- Weld Coupons

COMMON TEST STANDARDS AND CODES

Xenogenesis is experienced with many different industry standards and codes to include:

| Testing Standard | Common Material Analysis Testing Codes |

| API – American Petroleum Institute | 1104 (Welding of Pipelines and Related Facilities) |

| ASME – American Society of Mechanical Engineers | BPVC Section V, Section IX, B31.1, B31.3 |

| ASTM – American Society for Testing and Materials | E1444 |

| AWS – American Welding Society | D1.1, D1.2, D1.4, D1.5, D1.6 |

| AWWA – American Water Works Association | AWWA C200 |

| Client Specific | Customized Test Services |