Xenogenesis, llc

Structural steel is a type of steel that is primarily used in construction and engineering projects. It is a high-strength material that is capable of withstanding heavy loads and stresses, making it ideal for use in buildings, bridges, and other large structures. Structural steel is composed of a variety of elements, including carbon, manganese, phosphorus, sulfur, and silicon. It is typically produced in a range of grades and specifications to meet different construction requirements. The most commonly used grades of structural steel include A36, A572, and A992.

- Microscopy

- Bend Testing

- Visual Weld Inspection

- Verify Measurement

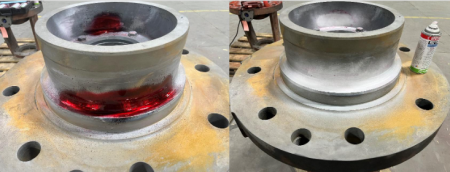

- Penetrant Testing

- Mag Particle Testing

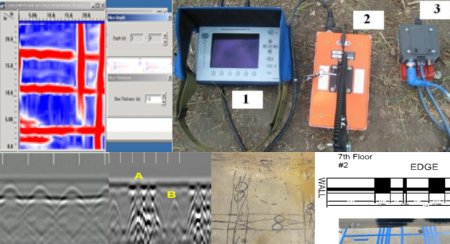

- Ultrasonic Testing

- Bolt Torque

- Load Testing

Visual Testing (VT) is a non-destructive testing (NDT) technique that involves examining the surface of a material or component to detect any visible defects or abnormalities. It is a widely used method for quality control and safety assessment in various industries such as aerospace, automotive, construction, power generation, and manufacturing.

During visual inspection, the inspector examines the surface of the material or component using the naked eye or with the help of magnifying lenses, cameras, or other visual aids. The inspector looks for surface cracks, corrosion, scratches, dents, and other surface irregularities that can affect the performance or safety of the component.

Penetrant testing, also known as dye penetrant inspection, is a non-destructive testing method used to detect surface-breaking defects in materials such as metals, plastics, ceramics, and composites. It is commonly used in industries such as structural, power generation, nuclear, aerospace, automotive, and manufacturing.

The process involves applying a liquid penetrant, usually a brightly colored dye, to the surface of the material being tested. After a period of time, the excess penetrant is removed, and a developer is applied. The developer draws the penetrant out of any surface-breaking defects, creating a visible indication of the flaw.

Magnetic Particle Testing (MPT) is a non-destructive testing method used to detect surface and slightly subsurface discontinuities in ferromagnetic materials. It is a highly effective method for detecting surface cracks, porosity, laps, seams, and other surface anomalies in materials such as iron, steel, and some nickel alloys.

In MPT, a magnetic field is applied to the material being inspected, and iron oxide or iron oxide-coated particles are dispersed over the surface. The particles are attracted to areas of magnetic flux leakage, indicating the presence of a discontinuity. The particles form a visible indication or indication pattern, allowing the inspector to locate and evaluate the size, shape, orientation, and depth of the defect.

XENOGENESIS – FIELD AND LAB TESTING SERVICES

is a non-destructive testing (NDT) firm

that has serviced the southeastern US

for over 20 years

Non Destructive Testing

& Laboratory Testing

the differance

of Xenogenesis

Xenogenesis, LLC (Xenogenesis) is a non-destructive testing (NDT) firm that has serviced the southeastern US for over 20 years and offers a full range of testing and inspection services. NDT methods include radar imaging, visual inspection, ultrasonic testing, penetrant testing, radiography, magnetic particle testing, positive material identification (PMI), and many others. Our team has extensive experience in radar imaging (GPR), non-destructive testing, inspection, and project management. Xenogenesis’ experience allows our team to work closely with your company and identify the best approach for your project.

-

1825 Lockeway Dr, Unit 206, Alpharetta, GA 30004, United States

-

This email address is being protected from spambots. You need JavaScript enabled to view it.